Scope of application

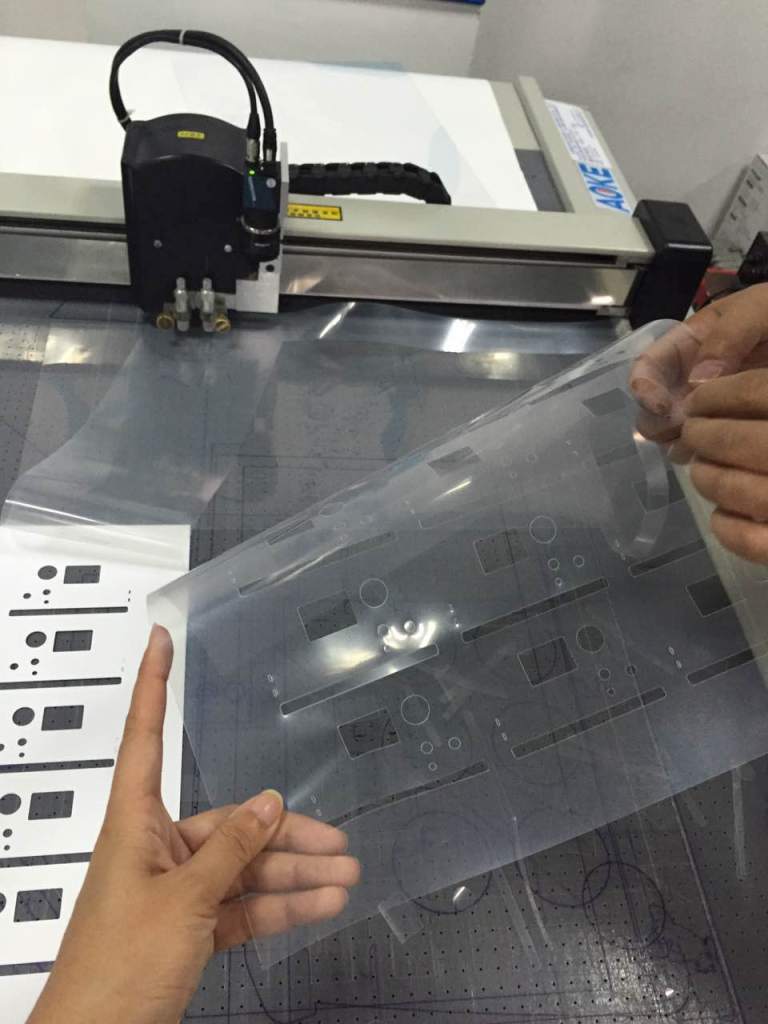

We can process insulation materials, optoelectronic materials, shielding materials, adhesive products in the electronics industry through die-cutting and cutting, sampling, and small batch production of insulation materials, optoelectronic materials, shielding materials, adhesive products, etc., as well as small batch production without cutting molds. It can process 1.5mm thick insulation materials, optoelectronic materials, shielding materials, adhesive products, with a maximum thickness of 2mm. It can cut through, half through, dotted lines, dots, and also draw high-precision knife mold drawings.

Import the CAD drawings that need to be cut into the Aoke Electronic Material Cutting Machine, set the cutting drawings using the Aokecut software that comes with the machine, determine the position and sequence of cutting half through and full through, and then lay the processed materials on top. Use the “Mi Paper Drawing Method” to align the processing positions. Press the “Start Processing” button, and the machine will start working. The vacuum suction pump will automatically turn on, fix the material on the workbench, and the machine will start processing in the originally set order. After processing is completed, the vacuum suction pump will automatically stop, remove the processed product, and the work will end.

E-mail: aokecut@163.com

Mobile phone /Wechat/Whatsapp:0086-15916997282

contact person: Betty

Leave a comment