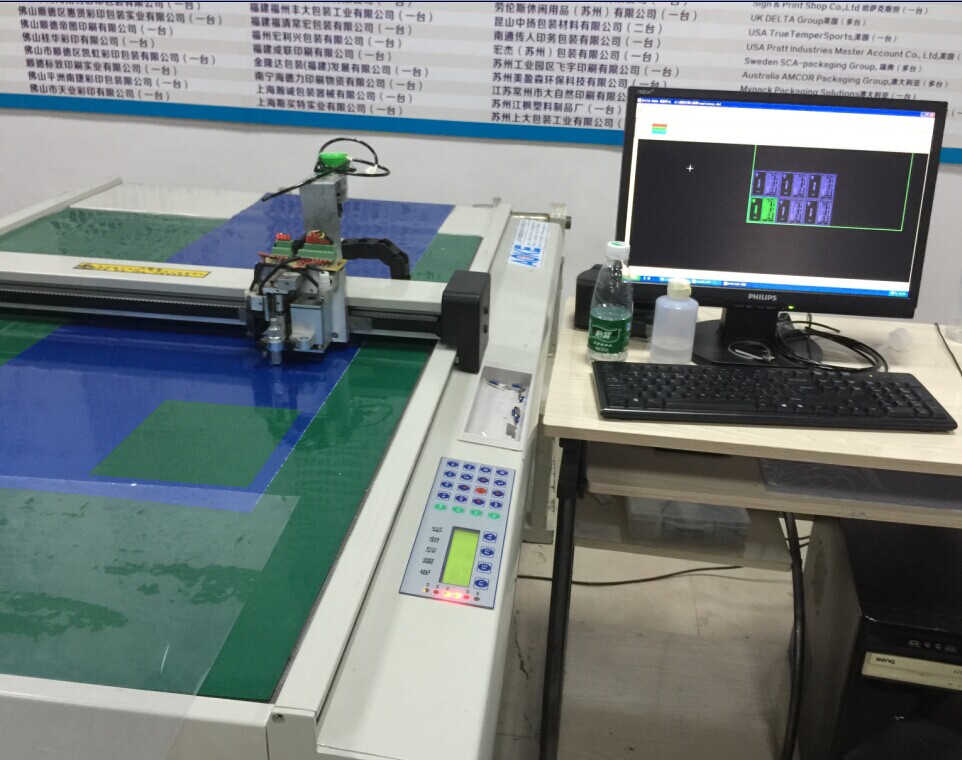

Aoke Electronic Materials Flat Die Cutting and Sampling Machine

1、 Cutting materials

1.1: Reflective material insulation material: such as LED lighting special thermal conductive silicone film, double-sided 3M thermal conductive film heat sink; Single hole silicon film, porous silicon film, etc; Insulated silicone tape, fiber free silicone tape, silicone tape gasket;

1.2: PVC, PET, PET, PP, PS, PE protective film 3M PORON FPC flexible board; Label folding box film switch masking tape; Double sided tape, backlight diffuse reflection shading double-sided tape material, button film switch, dimming film reflective film flexible circuit, optoelectronic products, adhesive products, dust-proof net, foam, thermal conductive material, insulation material PT、PET、 Precision die-cutting accessory materials such as film, protective film, copper platinum aluminum platinum, etc. with a thickness of about 2 millimeters for mobile phones, computers, televisions, electrical appliances, etc Mobile phone protective film, protective film, packaging film

2、 Applicable customer group:

Engaged in film switches, film windows, color box windows, printing films, flexible circuits, FPC board lamination, heat transfer printing, hot stamping, sound film diaphragm, laminated film base, adhesive backing paper, glue coating, silicon coating, motor gaskets, wire and cable strips, instrument panels, capacitor barriers, household appliance film stripping, vacuum aluminum plating, photoelectric backlight diffusion, optical touch screens, LCD, LED, DVD screen protection, lightbox advertising, lampshades, signage nameplates, automotive industry, electrical industry, healthcare, optical discs, packaging, printing, card making, food, toys, electronics, pharmaceuticals, experiments, LCD displays and other industries.

3、 Product Features:

The high-speed electronic material cutting machine provides a professional solution for the electronics industry, including multi specification, small batch, knife free, fast die-cutting and sampling. It is maturely used for cutting and processing materials such as FPC, PET, cover film, flexible circuits, thin film switches, optoelectronic materials, dust-proof nets, insulation materials, thermal conductive materials, and adhesive stickers. It has the characteristics of high cutting accuracy, low production cost, and fast delivery speed. Based on customer needs, we provide professional electronic material cutting services for different materials, design requirements, and die-cutting solutions. Our services include drawing, cutting, and indentation, as well as semi threading and dashed line cutting. Provide customers with the simplest and fastest die-cutting and sampling solution

E-mail: aokecut@163.com

Mobile phone /Wechat/Whatsapp:0086-15916997282

contact person: Betty

Leave a comment