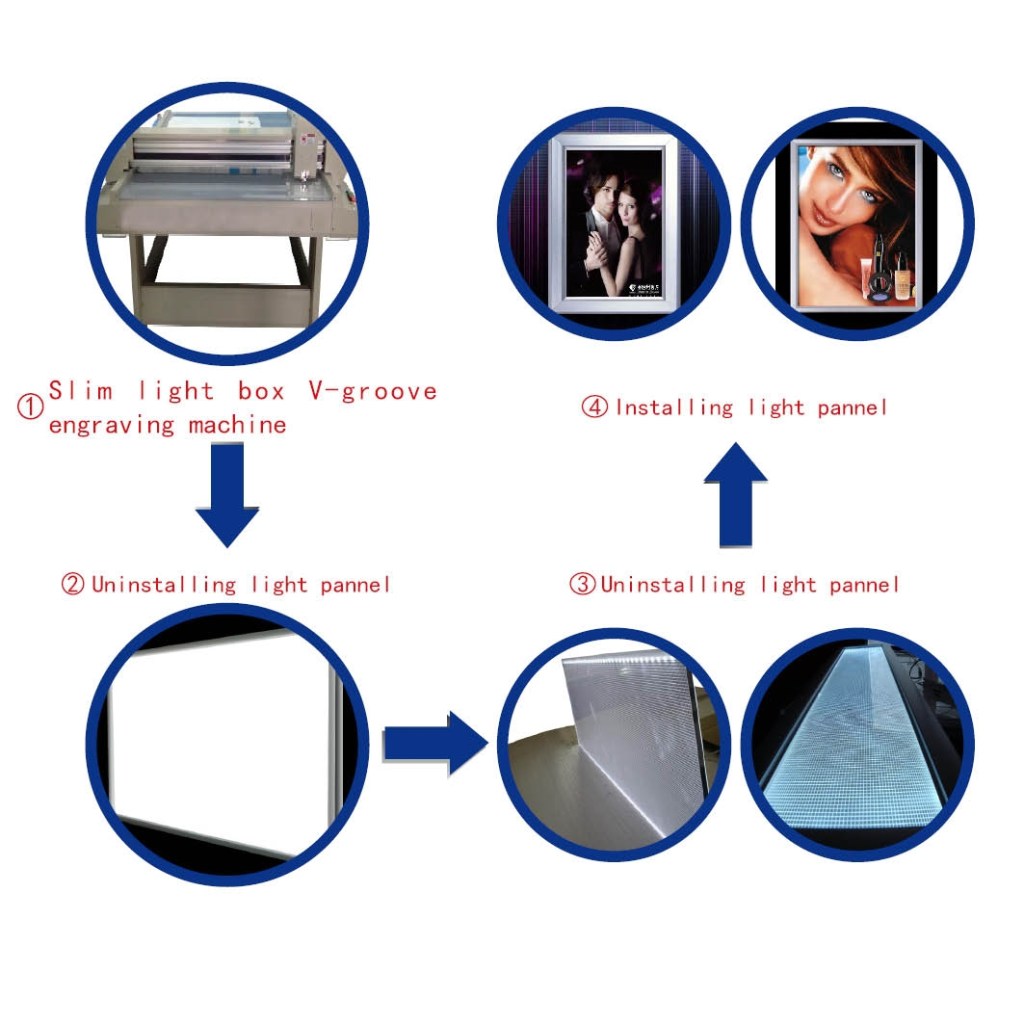

Effectively filling the gap in the manufacturing of laser cutting machines for domestic lightbox advertising, using traditional CNC blade cutting not only improves work efficiency and reduces costs, but also achieves better manufacturing results.

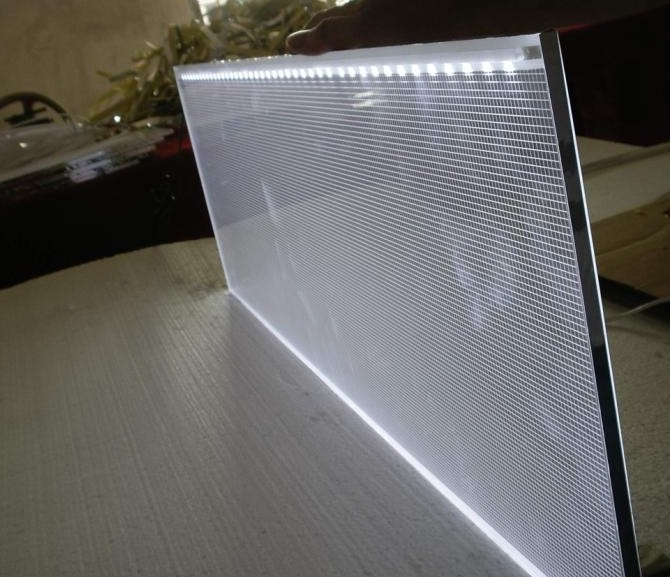

1. High precision: Professional light guide plate drawing machine, capable of drawing precise lines with uniform light, with a maximum accuracy of ± 0.05mm.

2. Good light guiding performance: The products produced have good light guiding effect, uniform astigmatism, and high light conversion rate (more than 40% higher than general light guiding plates).

3. Fast speed: High production efficiency, with an average drawing speed of 36000MM to 60000mm per minute.

4. Mold free: can depict any shape, can continuously modify the shape according to customer needs, can depict network lines and grids.

5. Good stability: Equipped with Panasonic servo drives and servo motor motors from Japan, it can work continuously 24 hours a day for mass production.

6. Convenient adjustment: It can effectively solve the problem of uneven thickness of the light guide plate itself, and the machine can automatically adjust according to the depth of the light guide plate lines.

7. Easy to operate: The machine is controlled by a fully automatic computer program, and new employees can operate line drawing, cutting, and carving processing on the machine after half a day of training, ensuring normal production.

8. Widely applicable: There are many types of materials that can be cut and carved, and they are widely used.

9. Full service: free home delivery, free on-site installation and debugging, free training until mastered. Free one-year warranty and lifetime maintenance.

Randomly equipped with knives and pens.

Reasons for choosing Aoke:

1. Good effect: Special blade cold cutting completely improves the drawbacks of burning, yellowing, and blackening caused by laser cutting.

2. Fast speed: High production efficiency, with an average drawing speed of 36000MM to 60000mm per minute.

3. High standard: Special blade cold engraving improves the disadvantages of large cutting seams and scratches in laser engraving, achieving industry standards of smooth cutting edges and 90 degree verticality.

4. Easy to operate: The machine is controlled by a fully automatic computer program, and new employees can operate line drawing, cutting, and carving processing on the machine after half a day of training, ensuring normal production.

Convenient adjustment: It can effectively solve the problem of uneven thickness of the light guide plate itself, and the machine can automatically adjust according to the depth of the light guide plate lines.

5. Environmental Protection: Compared to laser machines, it is pollution-free, odorless, and poses no harm to operators.

E-mail: aokecut@163.com

Mobile phone /Wechat/Whatsapp:0086-15916997282

contact person: Betty

Leave a comment