Suitable for sample production and small batch production, tailor-made revolutionary cutting solutions for enterprises such as shoemaking, luggage and handbags, car seats, aviation seats, furniture, clothing, etc.

Five major product advantages

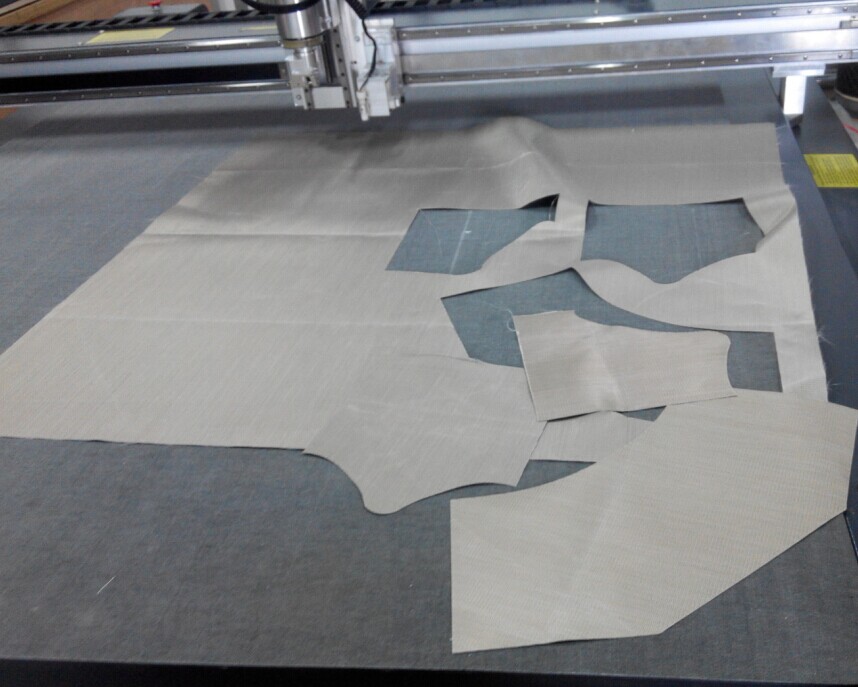

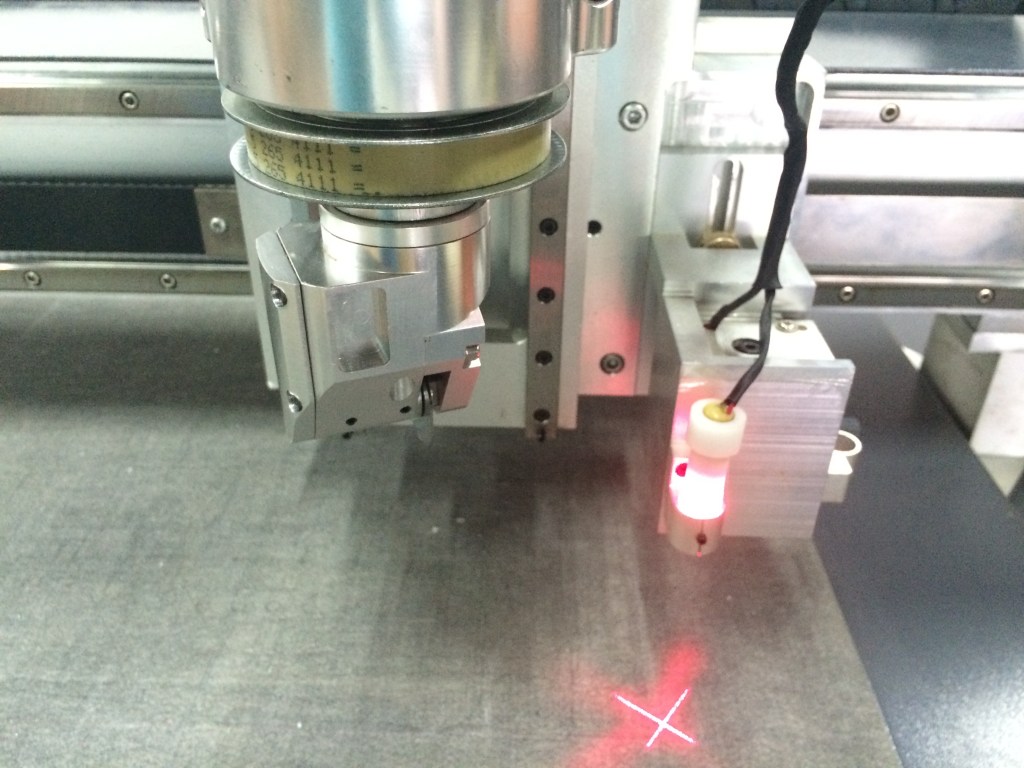

1. By adopting vibration knife cutting technology, there is no need to make knife molds, saving costs and time in the production and development process of knife mold manufacturing, management, storage, etc., completely bidding farewell to traditional manual knife mold cutting technology, completely breaking through the bottleneck of enterprises’ dependence on skilled workers, and taking the lead in entering the era of digital knife mold free processing.

2. Multi functional cutting head design, highly integrated with multiple sets of processing tools, can perform interactive cutting, punching, and marking in one work unit, achieving one-stop operation.

3. Being able to complete high difficulty, complex styles, and template cutting that cannot be achieved by cutting molds greatly expands the design space of designers, creating new styles that cannot be replicated by manual cutting, making your templates more attractive, and truly achieving the realm of “not afraid of not being able to do, but afraid of not being able to think” in design.

4. By accurately simulating various operation processes through computers, programmed operations are achieved, eliminating the interference of personal factors such as workers’ emotions, skills, and fatigue in traditional cutting, avoiding hidden waste, and thus improving material utilization.

5. It can achieve timely modification of templates, save development and board making time, quickly produce and modify boards, and adapt to rapidly changing market demands. The same board adjustment can lead your competitors by 2-3 days, helping you quickly seize market opportunities.

Fast – The cutting speed of Aoke CNC leather cutting machine is 4-6 times faster than traditional manual cutting speed, achieving fast cutting, fast discharging, and fast production, especially for customers with small order volume, multiple styles, and short delivery time.

Accurate – The Aoke leather computer cutting machine adopts computer control, and the safe distance of the sample can be precise to 0.1-1mm, with continuous cutting, avoiding laser cutting damage to the leather material and also avoiding manual errors in manual cutting, resulting in more accurate discharge and ensuring product quality.

Province – Aoke CNC leather cutting machine can increase the average material utilization rate by more than 5%, saving the direct cost of leather materials. Both genuine leather manufacturing enterprises

E-mail: aokecut@163.com

Mobile phone /Wechat/Whatsapp:0086-15916997282

contact person: Betty

Leave a comment